Mastering chocolate & candymaking for over 170 yearsTrusted by Confectioners

for Generations.

Candymaking

Candymaking equipment for both small and large scale production.

Explore

Chocolate

Melting and tempering tanks as well as ancillary equipment for chocolate production.

Explore

Lifting Equipment

LifTILTruk lifters designed for safe, easy pouring by one person.

Explore

See our best-sellers Popular Products

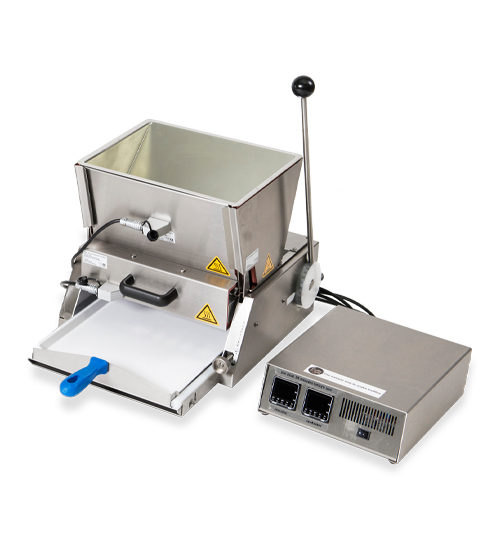

FireMixer-14 (FM-14)

FM-14 Tabletop Cooker-Mixer for Candymaking and Various Other Food Applications

A heritage of quality What People Love About Savage Bros

— Dwayne Hallan

Inductee, Candy Hall of Fame

Inductee, Candy Hall of Fame

★★★★★

"With 47 years in the confectionery industry, I’ve relied on Savage Brothers equipment for exceptional performance and durability. Their chocolate tanks, tables, cookers, and lifting solutions are indispensable for any confectionery operation—well worth the investment."

— Chuck Klauber

★★★★★

"We have been doing business with Savage Bros for over 40 years and highly recommend their products for small to medium sized manufacturers. The quality is very good, affordable and great phone service for parts and pricing."

— Robert Tompkins

★★★★★

"(Their) site is a very useful run-down of Savage Bros equipment and its uses. As the owner of several stores -Southern Candymakers of New Orleans- it provides guidance for buying new equipment for our expansion and for salvaging a number of older auction items."

— Tammera Bollman

★★★★★

"Dropped in at the Savage Bros location with no forewarning – everyone was welcoming, we got the full tour and were amazed at the high quality materials and craftsmanship involved in the manufacture of their equipment. I would recommend their equipment without reservation!"

— Kristen Bocanegra

★★★★★

"The response time, care, and professional expertise provided is absolutely incredible. I would highly recommend working with Savage Brothers. Based on my experience their commitment to excellence and interest in truly meeting a customer's needs is top notch."

High-quality, high serviceBuilt for Generations

Built to last for generations, Savage Bros equipment has become a time-honored tradition in the confectionery world, renowned for its unmatched durability and quality.